Top 5 Soundproofing Challenges in Industrial Spaces—and How to Solve Them

In today’s fast-paced industrial environments, managing noise levels isn’t just about comfort, compliance, safety, productivity, and employee well-being. Excessive machinery, equipment, and structural vibration noise can lead to hearing loss, operational inefficiencies, and even OSHA violations.

That’s where Hushtec MLV (Mass Loaded Vinyl) comes in—offering custom-engineered soundproofing solutions that tackle industrial noise at the source. This post breaks down the top 5 soundproofing challenges in industrial spaces—and how Hushtec MLV helps overcome them.

1. Machinery Noise and Vibrations

The Challenge:

Heavy-duty equipment such as compressors, generators, CNC machines, and hydraulic presses generate powerful airborne and structure-borne noise. This not only affects workers nearby but also radiates through walls and ceilings.

The Solution:

Hushtec MLV provides a high-density acoustic barrier that blocks sound transmission from vibrating machinery. It can be customized into wraps, enclosures, or composite panels to directly line machine housings—dramatically reducing decibel levels without interfering with maintenance access or ventilation.

2. Noise Leakage Through Walls and Partitions

The Challenge:

Thin, uninsulated walls are common in older factories and temporary structures. Sound leaks through these partitions easily, leading to cross-departmental noise pollution and decreased focus on production lines.

The Solution:

Hushtec’s flexible MLV rolls can be retrofit onto existing drywall, metal sheeting, or concrete, creating an instant acoustic barrier. For enhanced performance, it can be layered with foam or fiberglass in a decoupled wall system—customized to the wall’s material and thickness.

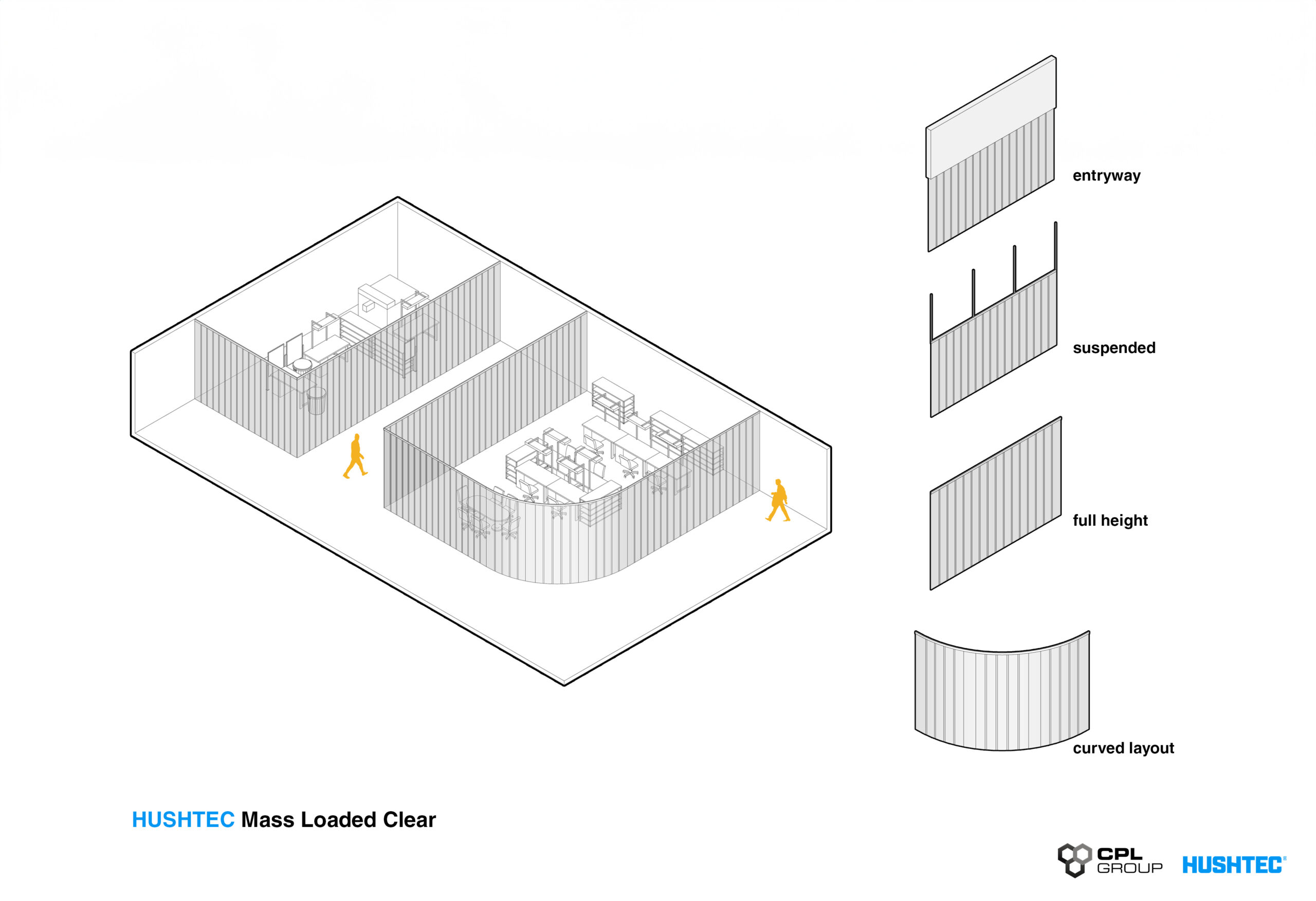

3. Open-Plan Layouts with Poor Acoustic Separation

The Challenge:

Large, open-plan workshops or fabrication bays lack proper acoustic zoning. This leads to sound bouncing around the facility, compounding noise and making communication difficult.

The Solution:

Hushtec offers modular MLV curtain systems and portable acoustic dividers, designed to contain sound within designated zones. These custom barriers are ideal for welding stations, test benches, or high-noise assembly areas—creating flexible “quiet zones” in open floor plans.

4. Sound Transfer Through Ceilings and Floors

The Challenge:

In multi-level industrial buildings, noise from one level can easily transmit through concrete slabs, metal decking, or lightweight floors—impacting offices or quality control labs above.

The Solution:

Hushtec MLV can be installed as an underlayment beneath flooring systems or suspended in ceiling cavities, adding substantial mass to dampen airborne and impact noise. Our custom-fit floor soundproofing systems are engineered to withstand heavy industrial foot traffic and loading.

5. Regulatory Compliance and Worker Safety

The Challenge:

Many facilities fail to meet legal noise exposure limits set by OSHA or local standards. Non-compliance risks fines, worker compensation claims, and declining employee morale.

The Solution:

By using Hushtec MLV in targeted high-noise areas, facilities can significantly lower sound pressure levels and document their mitigation efforts. Our acoustic consultants work directly with your team to design custom MLV applications that align with safety audits and noise mapping data.

Why Hushtec MLV Is Built for Industry

Hushtec MLV isn’t just a material—it’s a versatile, engineered soundproofing solution designed with industrial challenges in mind:

- High-density barrier (up to 5 kg/m²) for maximum performance

- Fire-resistant, non-toxic formulation for safe use in all environments

- Custom fabrication available for machine wraps, curtains, and wall panels

- Durability under heat, oil, and vibration exposure

Final Thoughts

Noise control is no longer optional in industrial spaces—it’s essential for safety, compliance, and operational excellence. With Hushtec MLV’s custom soundproofing solutions, you can tackle noise issues at the source, improve acoustic conditions, and support a healthier, more productive workforce.

Ready to transform your industrial space?

Let’s talk about a custom Hushtec MLV solution built for your environment.